Remember that episode of I Love Lucy where Lucy and Ethel have to wrap chocolates as they speed by on a conveyer belt? (Season two, episode one. Go watch it again, but come right back.) It’s overstated, of course. It’s comedy. But it also hits on many of the shortfalls of manual manufacturing processes: throughput, quality, scrap, a reliable workforce.

Compare that to the fully automated chocolate factories of today. Go ahead, google it. I’ll wait. There’s no doubt which of these two processes is more efficient, but what factors prompt the shift from manual to automated manufacturing? The path to automation is not always a straight and simple one. Your company’s goals are unique, and every industry has a particular set of variables. So how do you know when it’s time to consider automating your process?

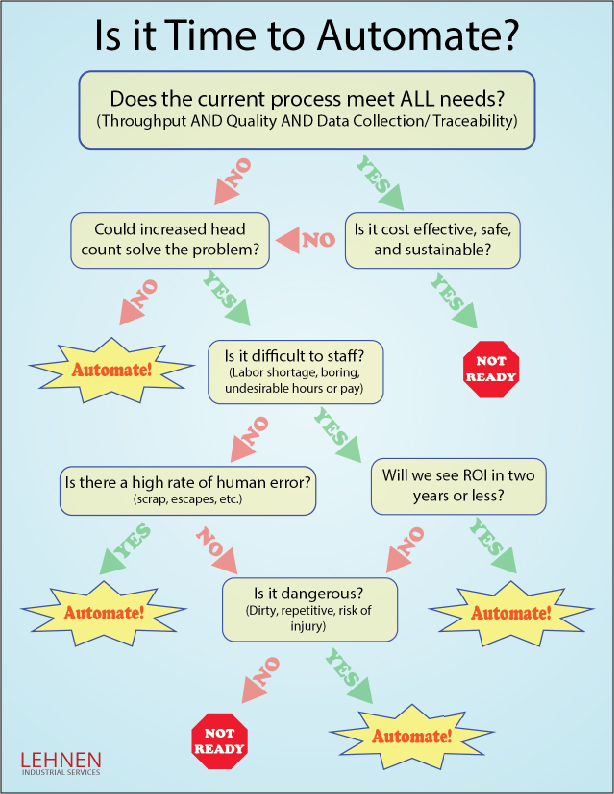

The good news is that, while every business is different, there are some basic considerations common to nearly all manufacturing processes, and asking the right questions can get you most of the way there. Is your current process manual and repetitive? Congratulations! You’re a candidate for automation. To know if automation is right for your company, we have to look a little deeper. Is the current process meeting all of your needs? Is staffing an issue? Are you having to squeeze your margins to stay competitive? Is your process sustainable? Is it dangerous? Let’s dig in.

Needs

When we talk about needs, throughput is often the first factor that comes to mind. It’s a big one, but it’s not the only one. In the not-so-distant past, limitations in functionality from automated systems made moving more units faster the primary measure of their worth. Today, with advances in vision, force sensing, and integrated guidance, some automated systems earn their keep without even considering process speed. Modern systems can incorporate in-line quality control with visual inspection and part verification. Data collection and part tracing happen in real-time, and that information can be immediately available for monitoring and reporting. High precision technology makes automated manufacturing possible for small and/or delicate components that may be difficult for human hands. It’s important to consider all of these needs collectively as we move forward, so “needs” will refer to throughput, quality, and data collection from now on.

Cost Effectiveness

So, let’s say you’ve asked yourself if your needs are being met, and the answer was yes. That means you’re done, right? Not so fast. Your process may produce all the quality parts you need, but is it cost effective? Dollars and cents rarely tell the whole story, but they are very intrusive narrators. While many companies start their automation journey with this question, it should only be the primary driver toward automation if all other needs and requirements are being met. This part of your evaluation will likely be highly specific to your company, and will have to be weighed against other benefits that may be less quantifiable, but ultimately more important. (Don’t worry, we’ll get to those in a minute.)

When calculating labor costs, it is important to consider the number of employees and/or work hours assigned to the process in question, their annual compensation, the rate of turnover and cost to train new employees, downtime due to absenteeism, and costs associated with ergonomic injury. Add in costs tied to human error like scrap rate, rework, and escapes (bad products that are inadvertently distributed). Examine your proposed automated solution and determine how many operators it will require times annual salary, costs associated with employee training, maintenance, and estimated downtime.

If you are considering updating or replacing an old automated system, or if you have specs detailed enough to estimate overall equipment effectiveness (OEE), that score can be a very useful tool in evaluating potential savings. Jonathan Trout does an excellent job explaining OEE and how to calculate it in his article in “Reliable Plant”.

Now that you have your numbers, subtract the labor and maintenance costs associated with the automated process from the labor costs you’re currently experiencing. Now, divide the cost of implementing your automated solution by your annual savings to see how many years it will take you to see a return on your initial investment (ROI).

The best way to get an accurate estimate of the cost of implementation is to work directly with an experienced integrator from the earliest stages of your project. If your system requires custom machine design, or your company serves a highly specialized industry, this first step is even more critical. Finding the right partner with experience in your industry will not only mean a more accurate quote, but will also give you the best chance of a successful outcome. Choose wisely.

Let’s say your cost of implementation will total $400,000, and your annual labor savings is $250,000. It would take roughly 1.6 years to realize your ROI. Any number equal to or less than two years is a strong indicator that automation is for you. But, as mentioned previously, financial considerations are only one piece of a much larger picture. It is entirely possible that automation could still be the right choice for you even if it will take five or more years to recoup your investment costs. What’s more important than money? I’m glad you asked.

Sustainability

We often think of sustainability in terms of environmental impact, and that is right and good. Automation very often helps companies lessen their impact on the environment through increased efficiency and decreased waste. But, sustainability also applies to the process itself and the human resources required to facilitate it. Staffing concerns are at the center of the sustainability conversation. We already talked about labor cost, but workforce sustainability is more than that. If you find that you struggle to maintain a full crew, your process is not sustainable. Whether due to labor shortages in your area or difficulty retaining employees due to undesirable hours, low pay, or unfulfilling tasks, an unpredictable or unreliable pool of laborers can cripple production. By contrast, even if your labor force is robust and capable, your company’s goals may simply have outgrown the capacity of a manual process.

Safety

Finally, is your process dangerous? Some risk factors to consider include ergonomic implications of repetitive tasks, heavy lifting, handling sharp components, pinch points, contact with chemicals, potentially inhaling aerosols, and the list goes on. Remember, you are not evaluating accidents that have happened, you are evaluating the potential for accidents, or long-term-exposure illnesses and injury.

Safety should be the last variable you consider. Not because it is the least important factor, but because it is the most important. Your manual process could very well pass all other areas of scrutiny and still be an excellent candidate for automation simply because the risk of injury and/or illness is too high.

Final Thoughts

Sometimes the decision to automate is simple and obvious. When it’s not, make sure to ask the right questions and be objective and thorough as you collect your data and weigh your options. If your results indicate that your company is not ready to adopt an automated process, remember to reevaluate every three to five years, or anytime a key consideration experiences major change. Have you seen a surge in demand? Reconsider automating. Has a pandemic decimated your labor pool? Reconsider automating. Have costs shifted in a way that makes the ROI timeframe more favorable? Reconsider automating. And if your employees have to stuff their mouths and shirts with parts to keep up, don’t consider. Just automate.

Ready for the Next Step?

If you have a process that would benefit from automation, drop us a line.