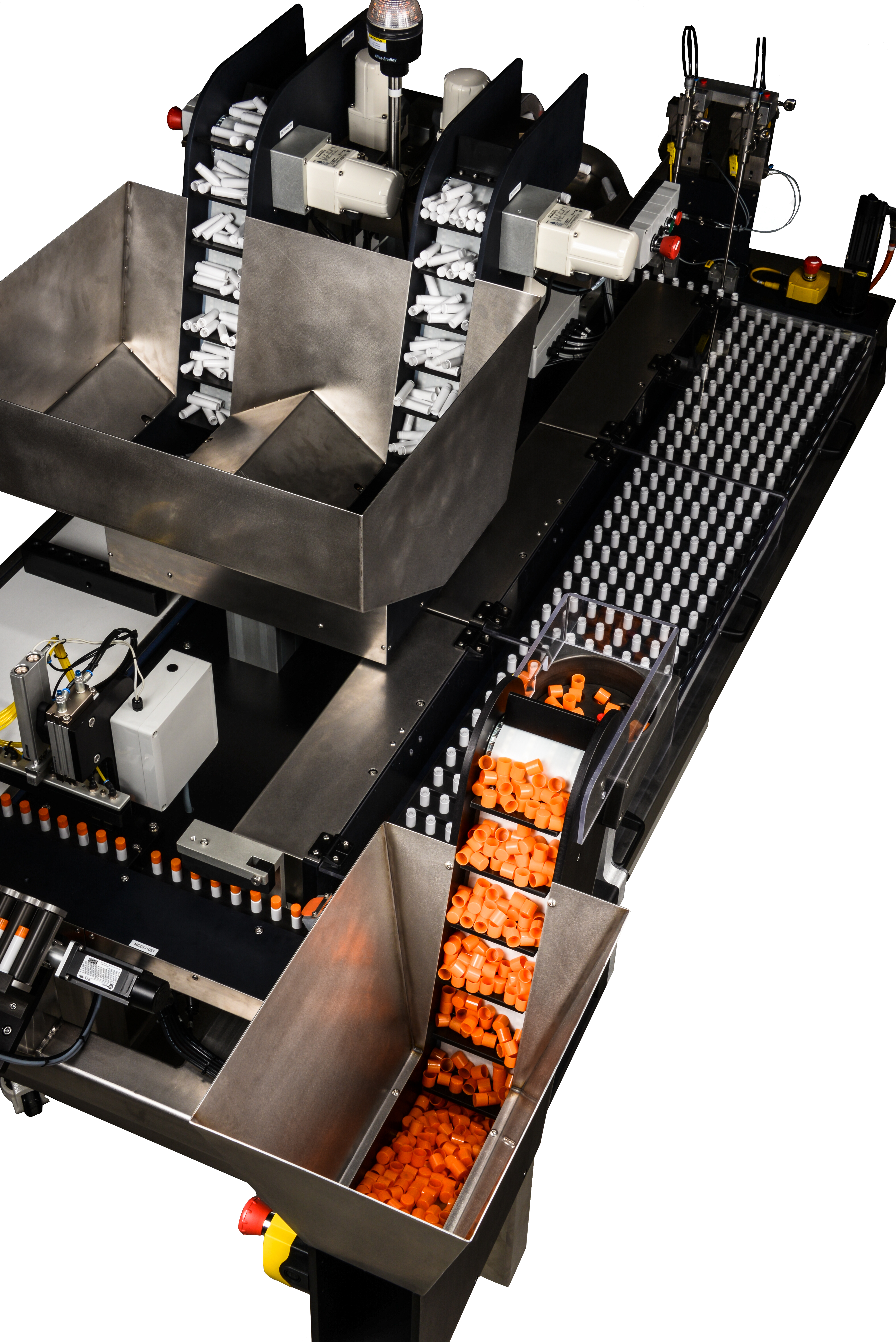

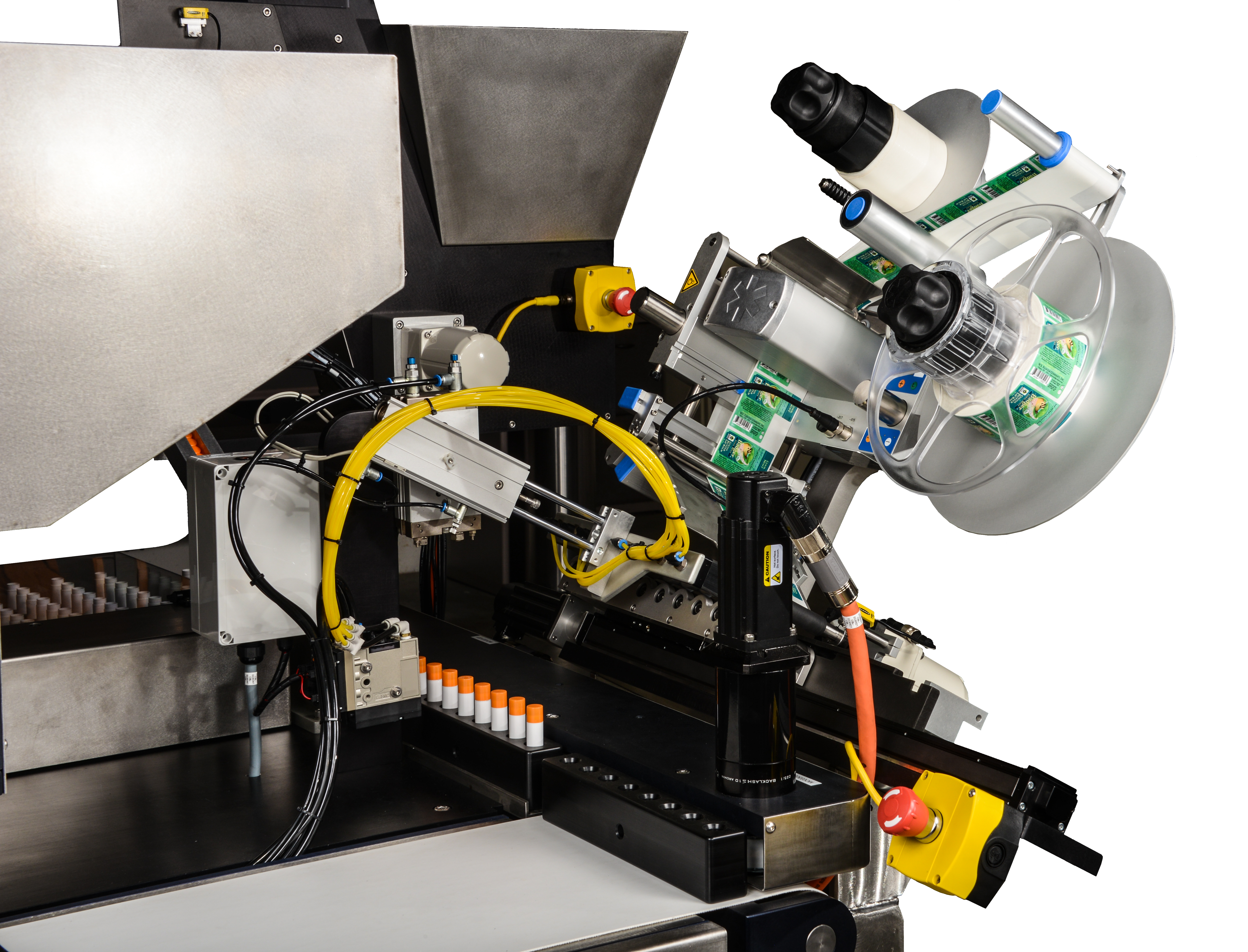

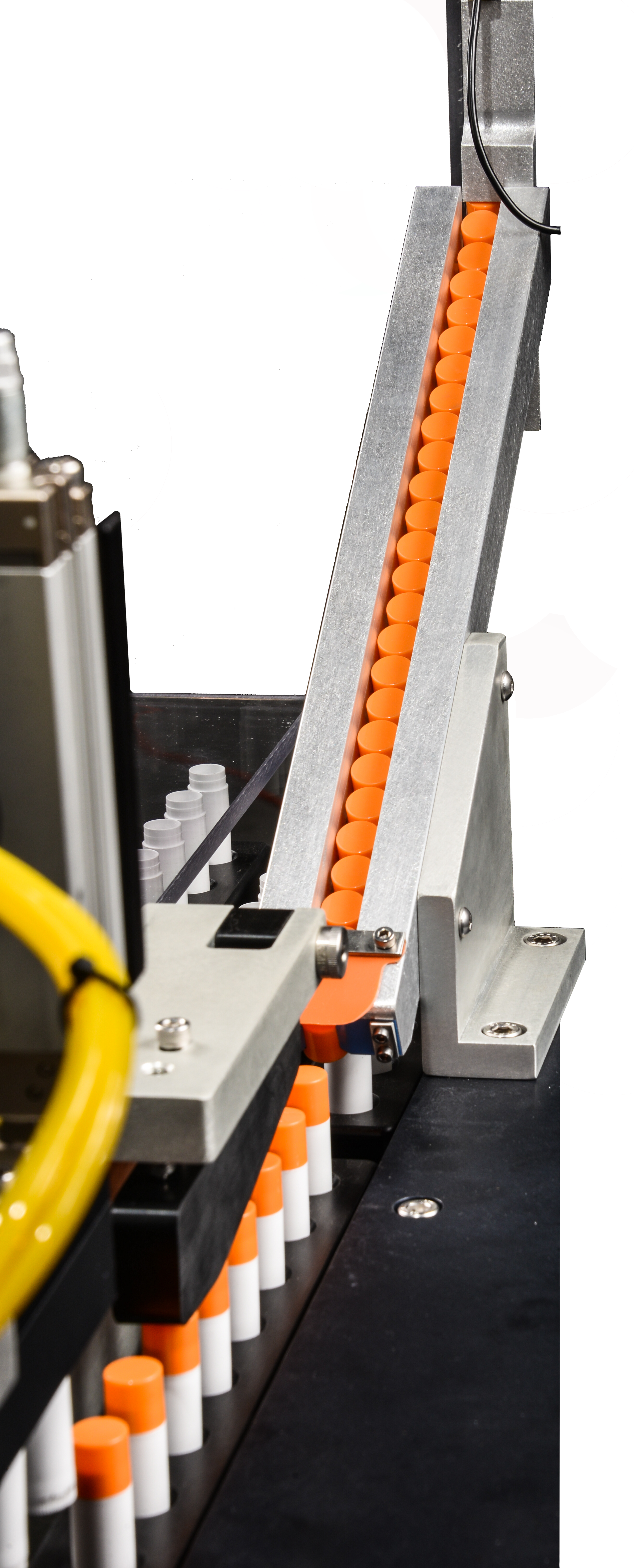

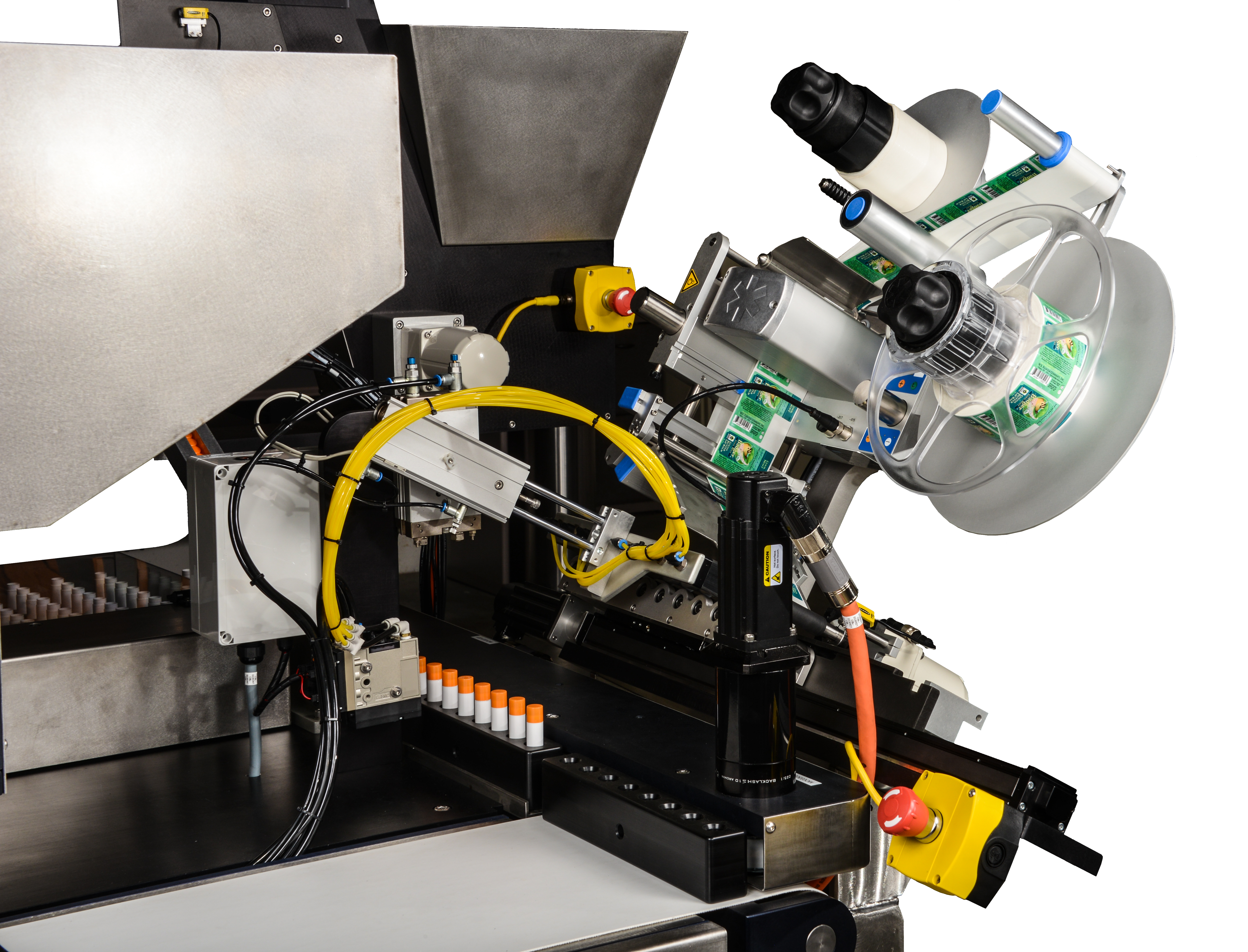

LOADING, FILLING, REFLOW, CAPPING, AND LABELING IN ONE SELF-CONTAINED UNIT

The new ProFill SF lip balm filler from Lehnen Industrial Services is changing the world of lip balm manufacturing. Whether you are looking to bring outsourced filling in-house, or your demand has saturated your current in-house process, our patented machine offers unique features that will meet all of your needs.

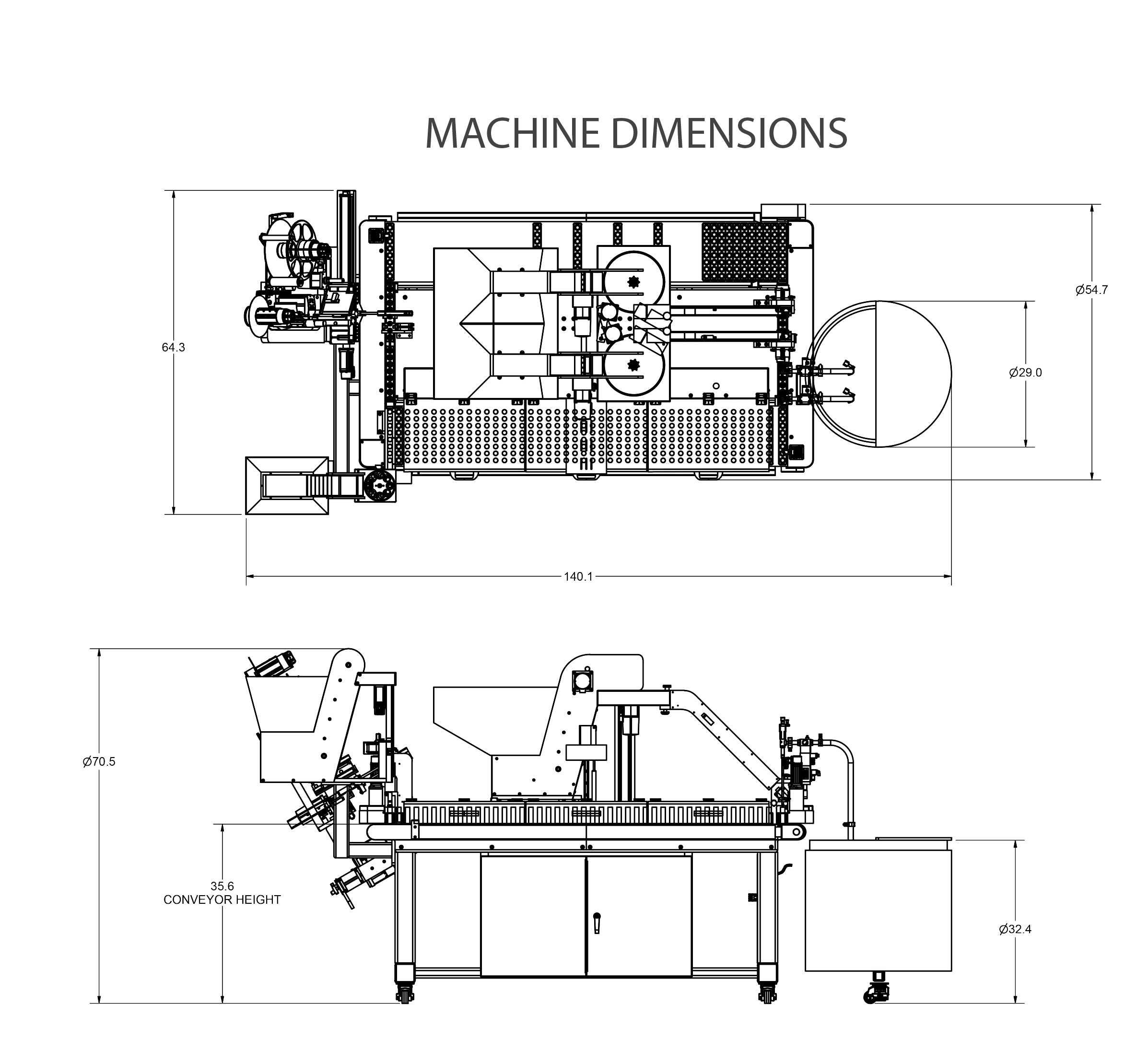

Compact

The ProFill SF has an impressively small footprint of 11 feet 8 inches (308 cm) by 5 feet 5 inches (142 cm). That’s your entire lip balm production line in less space than it takes to park a Mini Cooper.

Portable

The ProFill SF requires no installation other than a single outlet for 208-240 VAC. That, coupled with its size, allowed us to put the whole unit on wheels. Your limited space just became a lot more flexible.

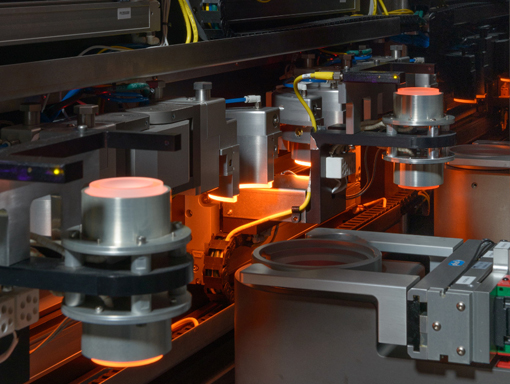

Robust Construction

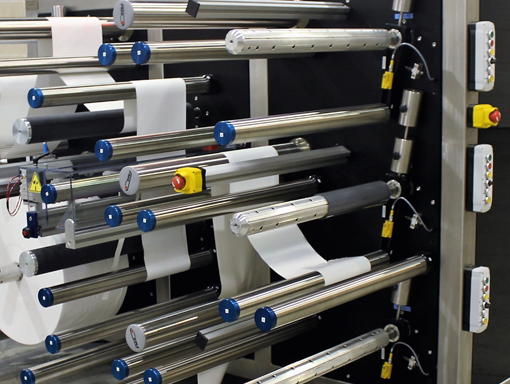

From the stainless-steel frame to the precision valve fillers, every component of the ProFill SF is designed to be clean-room compatible and keep your investment running high volume for decades.

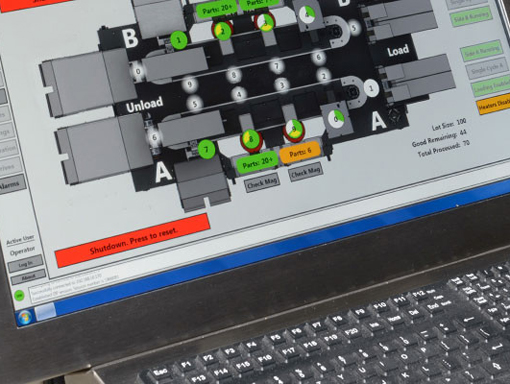

Self-contained

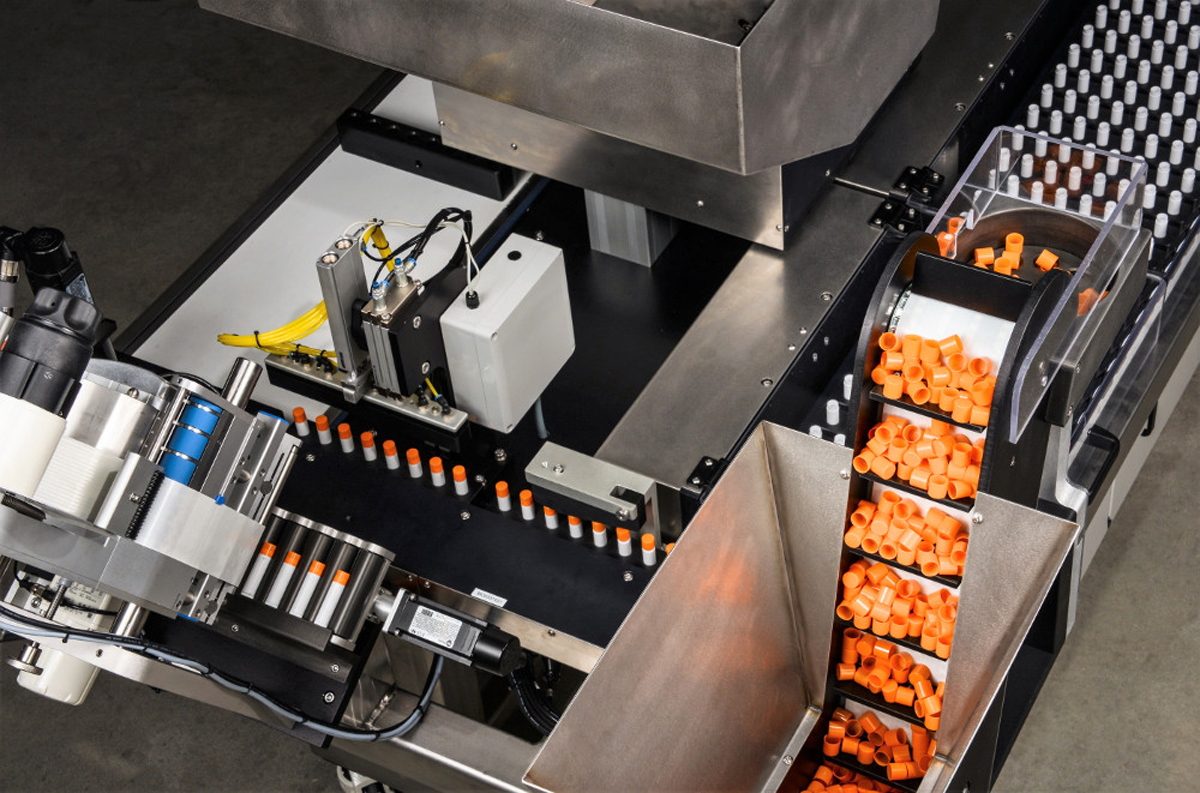

Your entire process is accommodated with one unit. Once the tanks and hoppers are filled, your work is done. Simply collect your capped and labeled sticks at the other end.

60 Sticks Per Minute*

Throughput is the name of the game. With numbers that rival (or beat) set ups with three times the footprint, the ProFill SF boasts the highest production per square foot on the market. Both the cap and tube hoppers hold 3600 containers, at least one hour of production.

*Based on standard sizes

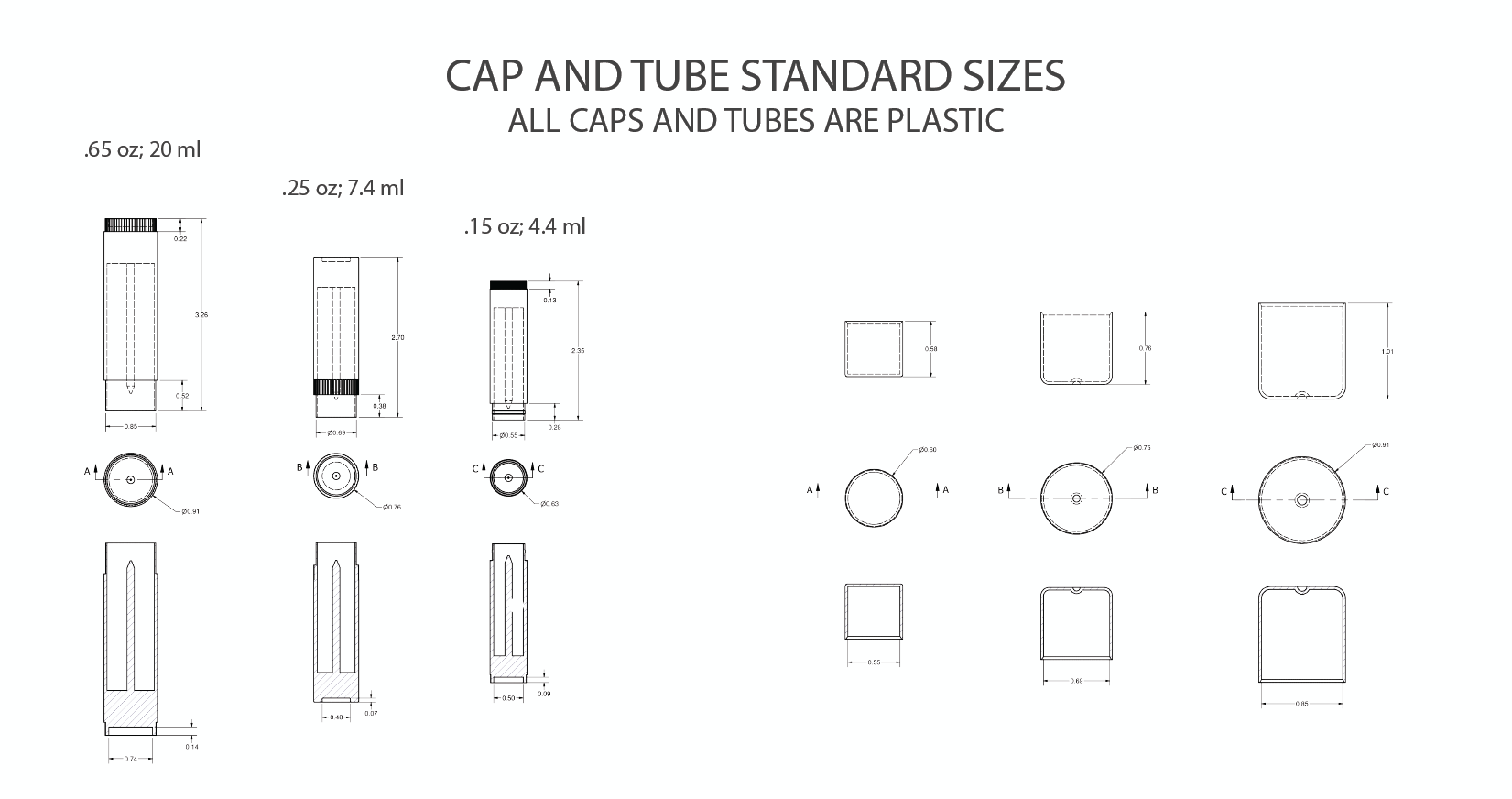

Multiple Tube Sizes

The ProFill SF is designed to accommodate a variety of industry standard sizes. Tooling changeover takes approximately one hour. Custom sizes may be possible as well. Send us your samples and we’ll work with you to make it happen.

Customizable

Your process is unique, and so are your needs. If you thought, “That would be perfect, if…” that’s okay! We’re engineers. We can customize the ProFill SF to fit your precise needs and make our machine serve your process.

Compact

The ProFill SF has an impressively small footprint of 11 feet 8 inches (308 cm) by 5 feet 5 inches (142 cm). That’s your entire lip balm production line in less space than it takes to park a Mini Cooper.

Portable

The ProFill SF requires no installation other than a single outlet for 208-240 VAC. That, coupled with its size, allowed us to put the whole unit on wheels. Your limited space just became a lot more flexible.

Robust Construction

From the stainless-steel frame to the precision valve fillers, every component of the ProFill SF is designed to be clean-room compatible and keep your investment running high volume for decades.

60 Sticks Per Minute *

Throughput is the name of the game. With numbers that rival (or beat) set ups with three times the footprint, the ProFill SF boasts the highest production per square foot on the market. Both the cap and tube hoppers hold 3600 containers, at least one hour of production.

*Based on standard sizes

Multiple Tube Sizes

The ProFill SF is designed to accommodate a variety of industry standard sizes. Tooling changeover takes approximately one hour. Custom sizes may be possible as well. Send us your samples and we’ll work with you to make it happen.

Self-Contained

Your entire process is accommodated with one unit. Once the tanks and hoppers are filled, your work is done. Simply collect your capped and labeled sticks at the other end.

Customizable

Your process is unique, and so are your needs. If you thought, “That would be perfect, if…” that’s okay! We’re engineers. We can customize the ProFill SF to fit your precise needs and make our machine serve your process.

PRODUCT SPECIFICATIONS

ProFill SF Gallery

Click here to see more photos of the ProFill SF

“The attention to detail is over the top, which is why I like working with Peter. He thinks about things most people wouldn’t think about.”

“A tenth the size of [other systems] on the market, and very reasonably priced.”