Cytiva is a global biotechnology research company that helps pharmaceutical companies deliver the next generation of novel therapeutics. At their Logan, Utah facility, Cytiva manufactures their own containers (PVC and platinum-cured silicone tubes) designed to hold cell culture media, the liquid cell food.

“Our product is like a raw material for our customers, who produce vaccines and medicines and therapies,” explained Ryli Martinez, Manufacturing Engineer at Cytiva.

“I just definitely want to emphasize that Lehnen was really easy to work with, very accommodating and built a solid product. They’re a good team, so we’ll keep working with them for future projects.”

This product has a direct role in vaccine production, and the filled containers end up at manufacturers like Moderna and Pfizer for manufacturing vaccines. In fact, the work of Cytiva’s team has helped produce Pfizer and Moderna vaccines during COVID-19 pandemic and into the present day.

Ready to tackle automation challenges? Start by telling us about your project.

Moving Cytiva away from a manual process

Ahead of an upcoming expansion project, Ryli and the Cytiva team had two directives in mind:

- Vertically integrate more of the production process.

- Significantly reduce lead times.

This led the Cytiva team to search for something more efficient than their manual tube cutter.

They had worked manually for years. It was slow and cumbersome for the team.

“It’s similar to a paper cutter, right?” said Ryli. “But then there’s a ruler attached to it, and you’d have to manually measure out your tube, then cut. If you can imagine doing that hundreds of times, and it probably takes an operator 30 seconds to do that cut.”

If they wanted to match the pace of their company’s growth, they needed a faster tube cutting system. A capital expansion project led their team to make the switch to an automated solution.

Here’s how we worked with Ryli and the Cytiva team to guarantee an efficient, clean, and precise cutting solution for their operation with the ProCut AF.

Evaluating exact needs for automation

To support this production change, Cytiva needed an automatic tube cutter that could meet strict standards for cleanliness and accuracy.

Factors to consider as Ryli looked at options for automation equipment included:

● Accurate and consistent cuts. Cytiva to meet the following tolerances:

○ Tube lengths <1’ ± 1/4”

○ Tube lengths ≥ 1’ ± 1”

● Compatibility with ISO 7 cleanroom standards. Arguably the most important consideration, the machine needed to be clean and not create any particulate matter.

● As compact as possible. While they didn’t have any specific square footage requirements, Ryli noted they needed to be mindful of space within the 10,000 square foot facility.

Finding the best-fit automation solution for the customer

The ProCut AF is a patented piece of equipment designed and built by Lehnen.

It is the first machine to automatically and accurately measure and cut tacky tubing without the need for alcohol, water, or compressed air (read the origin story here).

The equipment advances the technology for processing medical tubing in a clean room environment, providing alcohol-free tube cutting with automated precision. Cytiva selected the Lehnen machine over the competitor because the ProCut AF has an alcohol-free cutting solution and it creates no particulates.

By choosing the Lehnen ProCut AF machine, Ryli and the Cytiva team were able to achieve more precise cuts. The level of accuracy varies depending on the diameter and material being cut, but on average the machine delivers cuts within ±0.005 inches of variation per linear inch of length. This degree of precision falls well within the required tolerance thresholds. With the ProCut AF, they can reliably automate the cutting process by removing manual labor from their operation

Ryli can reduce overhead and pass savings on to customers, and report a successful equipment integration for a completely new production line.

Other innovations of the Lehnen automation solution:

No reliance on alcohol

Isopropyl alcohol (IPA) is often used in cleanroom environments as a lubricant, helping material move smoothly through the bushing during processing.

But it has its downsides: It’s another item that requires storage space, and there’s a specialized (and expensive) disposal process to get rid of the used-up IPA. Plus, it tends to get everywhere.

“It’s another consumable that you have to stock in a cleanroom,” explained Ryli. “And cleanroom space for us is valued around a thousand dollars a square foot.”

Improved wheel design versus traditional treading

It was important for Cytiva to minimize particulate matter during production, as it can lead to contamination within the cleanroom environment.

When treading is the mechanism used to move tubing through the process, the treads can generate small amounts of dust. This can risk the viability of products for shipping, causing product waste and reducing output.

Instead, the ProCut AF uses a wheel design to move tubing along. The wheels are made out of aluminum and are hard-coated, creating a smooth, particulate-free surface for processing the product.

Easily movable across the facility

The ProCut AF is easily moved around Cytiva’s facility and plugs into a standard 120V outlet to power up. Plus, accessible tool storage allows for a smart use of space in the clean room environment.

“Our culture at Cytiva is we’re constantly doing continuous improvement projects. What that means is our room changes configurations quite frequently. So, we knew that was going to be a consideration.”

And as far as the training on the new equipment for the expansion project, feedback from operators is already positive.

“Out of all the equipment in the room, the Lehnen was by far the easiest to train,” said Ryli.

On-call partnership & support

Once Cytiva completed their order, we promptly began building the two machines to replace their manual process.

At Lehnen Industrial Services, we do all of our own software engineering and production in-house — and our team is quick to respond for a piece of tooling or a replacement part.

“I really appreciate the fact that they have all that capability in-house and they can react quickly to help serve us better, which helps us serve our customers better,” said Ryli.

The equipment has been used in official production since September 2023, and both machines get used daily by the team. Thanks to easy equipment commissioning, Ryli’s time is now freed up to focus on other areas of the operation. And the door is still open for future process improvement initiatives.

“I just definitely want to emphasize that Lehnen was really easy to work with, very accommodating and built a solid product,” said Ryli. “They’re a good team, so we’ll keep working with them for future projects.”

Talk to Lehnen — the automation experts

In addition to manufacturing patented products like the ProCut AF, we pride ourselves on building machines from the ground up.

Since 2001, Lehnen Industrial Services has specialized in building custom automation equipment that helps customers succeed. Meet the demand for more productive processes with our purpose-built automation systems.

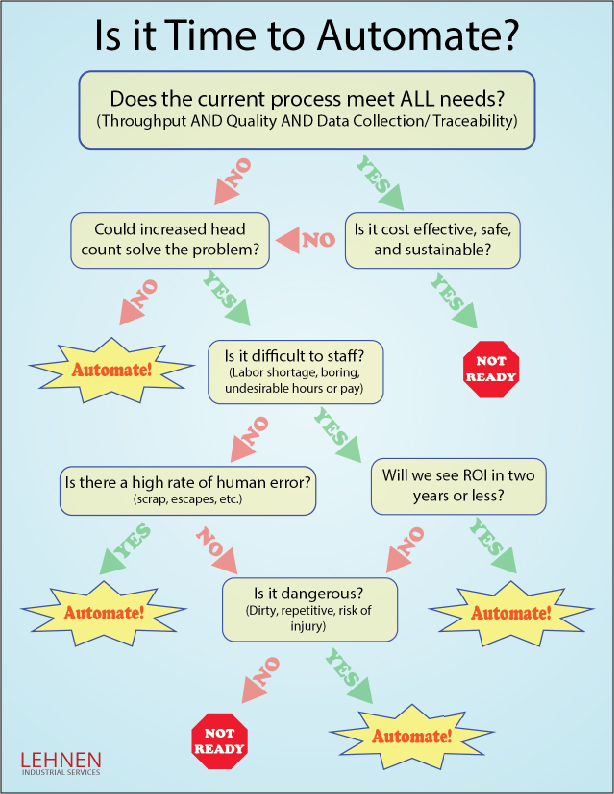

Wondering if it’s time to automate?

Click the image and download this simple decision tree to get started.

Ready for the Next Step?

If you have a process that would benefit from automation, drop us a line.