What We Do

Lehnen Industrial has provided process control and custom machinery for our customers since 2001. In that time, we’ve helped companies in life sciences, manufacturing, and web processing automate their processes. We help them achieve their manufacturing targets with precision, purpose-built equipment and inspired programming. Our team combines our expertise in design, engineering, and software with the customers’ input to innovate unique solutions for their specific needs.

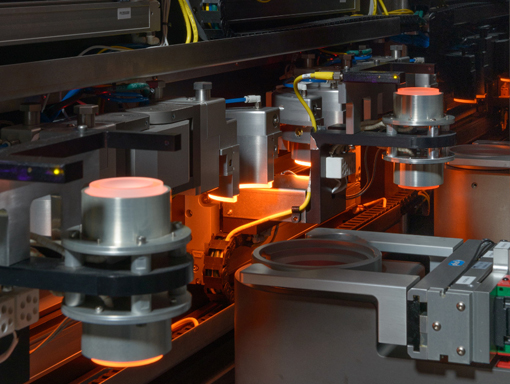

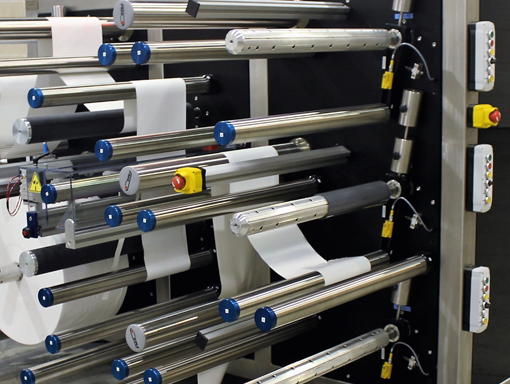

Purpose-built with Style

Our equipment balances form and function in purpose-built machinery that will look great on your production floor while meeting highly specific manufacturing requirements. Every piece of equipment adheres to all appropriate standards and comes with comprehensive documentation.

Purpose-built with Style

Our equipment balances form and function in purpose-built machinery that will look great on your production floor while meeting highly specific manufacturing requirements. Every piece of equipment adheres to all appropriate standards and comes with comprehensive documentation.

A One-Stop Shop

Our in-house engineering and fabrication capabilities allow for total start to finish control of the project. From initial concept sketches to final assembly, our team is hands-on and in close communication with your team every step of the way. When your build is complete, we are here to help with the factory acceptance test process.

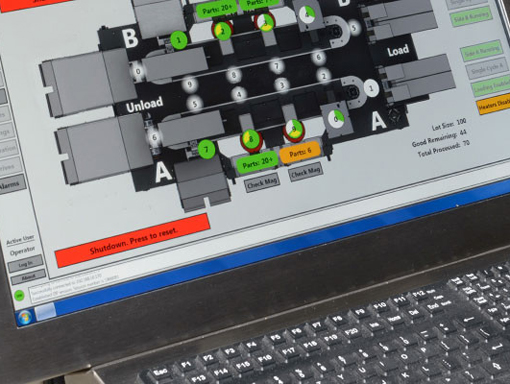

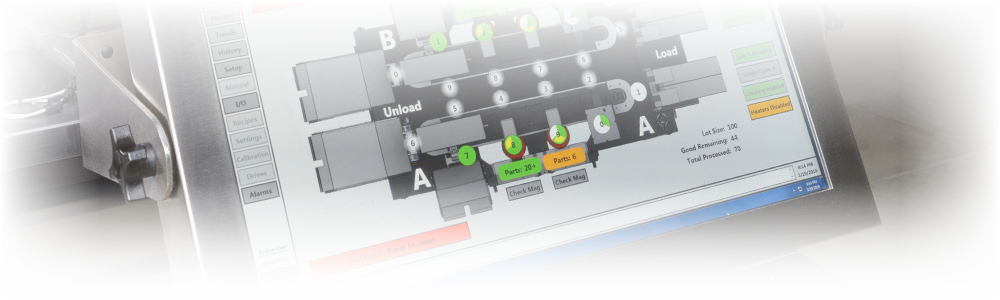

Custom Software

Our software team strives to present users with clean and sensible interfaces, easy navigation, and integrated help functionality, all built from the ground up for every machine we make. We have experience working with PanelView, Beijer, and RedLion interfaces, and have also developed our own PC based HMI system that unlocks the full capabilities and flexibility of the .Net framework. We create modular controls with easy to read code capable of handling complex processes, detailed recipes, and multiple modes of operation using the latest PLC hardware.

Custom Software

Our software team strives to present users with clean and sensible interfaces, easy navigation, and integrated help functionality, all built from the ground up for every machine we make. We have experience working with PanelView, Beijer, and RedLion interfaces, and have also developed our own PC based HMI system that unlocks the full capabilities and flexibility of the .Net framework. We create modular controls with easy to read code capable of handling complex processes, detailed recipes, and multiple modes of operation using the latest PLC hardware.

Ignition by Inductive Automation

We have also recently partnered with Inductive Automation as an integrator for their powerful Ignition program. Ignition is a web-launched controls system that seamlessly connects data from the plant floor to the top floor, and everywhere in between. As customizable as our equipment designs, Ignition is a built-to-suit program that works on any major operating system and puts control of SCADA, HMIs, alarms, reports and more at your fingertips from anywhere at any time.

“The learning curve was impressively quick. We had a four-month window, which Lehnen hit.”