Thursday, April 23rd

LinkedIn Mastery: Profile, Prospecting & Pipeline

A Strategic Workshop for Industrial Sales & Marketing Leaders

In industrial markets, relationships drive revenue, but your buyers are on LinkedIn before they ever pick up the phone. Are you showing up where it matters?

LinkedIn Mastery is a hands-on strategic workshop designed specifically for industrial manufacturers and the sales and marketing leaders who drive their growth. Whether you’re trying to break into new accounts, shorten your sales cycle, or build a pipeline that doesn’t rely solely on referrals and trade shows, this workshop gives you the system to do it.

We’ll show you how to transform LinkedIn from a digital résumé into a revenue-generating machine, using proven strategies tailored to the complex, relationship-driven world of industrial sales.

What we’ll cover:

- Profile Optimization: Build a profile that speaks directly to your ideal customer, establishes credibility, and compels action

- Prospecting Strategy: Learn how to identify and connect with key decision-makers at target accounts, including multi-stakeholder navigation common in industrial sales

- LinkedIn Sales Navigator: Master the platform’s most powerful tool for finding, filtering, and tracking high-value prospects

- Content & Thought Leadership: Develop a simple content strategy that keeps you visible and top-of-mind with your network

- Messaging & Outreach: Craft connection requests and messages that actually get responses — without feeling pushy or generic

- Team Alignment: Align your sales and marketing efforts on LinkedIn for a unified, consistent brand presence

This isn’t theory. This is a blueprint, and you leave with it in hand.

Built for: Sales leaders, marketing directors, business development professionals, and C-suite executives in industrial manufacturing who are ready to turn LinkedIn into a serious business development tool.

Time: 1pm-4pm

Address: 809 Court Street, Keene, NH 03431

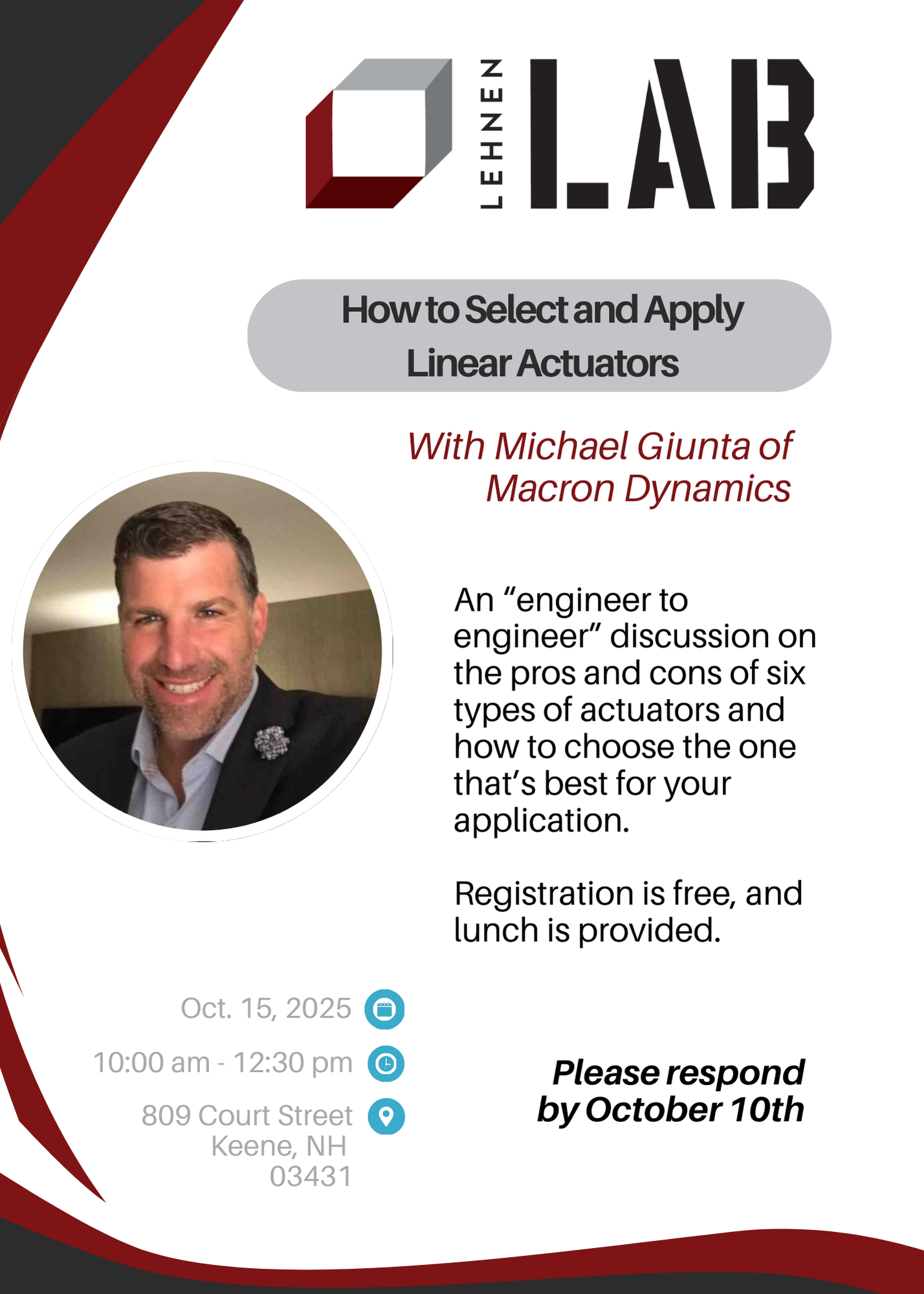

How to Select and Apply Linear Actuators

Michael Giunta, Macron Dynamics

If you are a mechanical engineer involved in speccing components and/or designing machines, this discussion is for you.

Take advantage of Michael’s expertise during the session, and continue the conversation over lunch.

Michael Giunta is a mechanical engineer who has held a variety of engineering and management roles with Exlar Corporation, AHTD, Stober Drives, Pawling Corporation, and The Lee Company. He has a strong mechanical engineering background with customer centric problem solving skills and extensive industry knowledge.

“Working with Lehnen has been an absolute pleasure. We share a lot of the same values, Igus and Lehnen, [like] accessibility and democratization of resources. Typically testing and automation are reserved for those who can afford it. But with Lehnen, you now have the ability for all tiers to access it and make use of it.”